Semi-Automatic Mechanical Rolling Bending Machine for 8mm Carbon Steel

$68,000.00 $33,100.00

Category: Mechanical Products

Description

Semi-Automatic Mechanical Rolling Bending Machine for 8mm Carbon Steel

Product description

This machine is a three-roller symmetrical upward adjustment type, mainly used for bending metal plates with a maximum thickness of 4mm during operation.At normal temperature, the plate rolling machine can roll the metal plate into a cylindrical shape, a conical shape, or a circular arc. The remaining straight parts

at both ends can be beaten into an arc by a manual hammer. The roll can be rolled into a small diameter cylinder or rolled. The metal plate with high surface quality(the upper and lower rollers can be affixed with a layer of adhesive tape) is a very general-purpose equipment. It is one of the main key equipment in the manufacture of boilers, shipbuilding, petrochemicals, cement, and motors. This equipment has the advantages of simple structure, compact, convenient operation and high efficiency.

Be the first to review “Semi-Automatic Mechanical Rolling Bending Machine for 8mm Carbon Steel” Cancel reply

Related products

-

Compare

Semi-Automatic Mechanical Rolling Bending Machine for 8MM Carbon Steel 3000 Length Processing Production Tool Sale

0 out of 5(0)Semi-Automatic Mechanical Rolling Bending Machine for 8MM Carbon Steel 3000 Length Processing Production Tool Sale

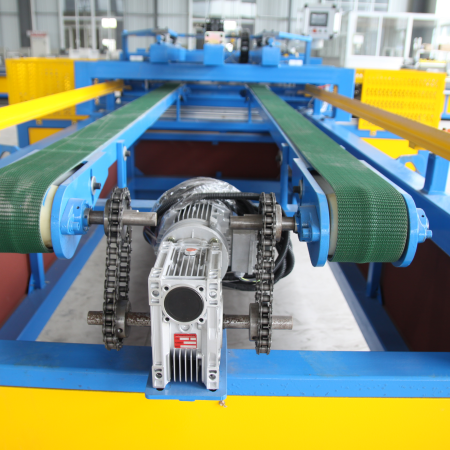

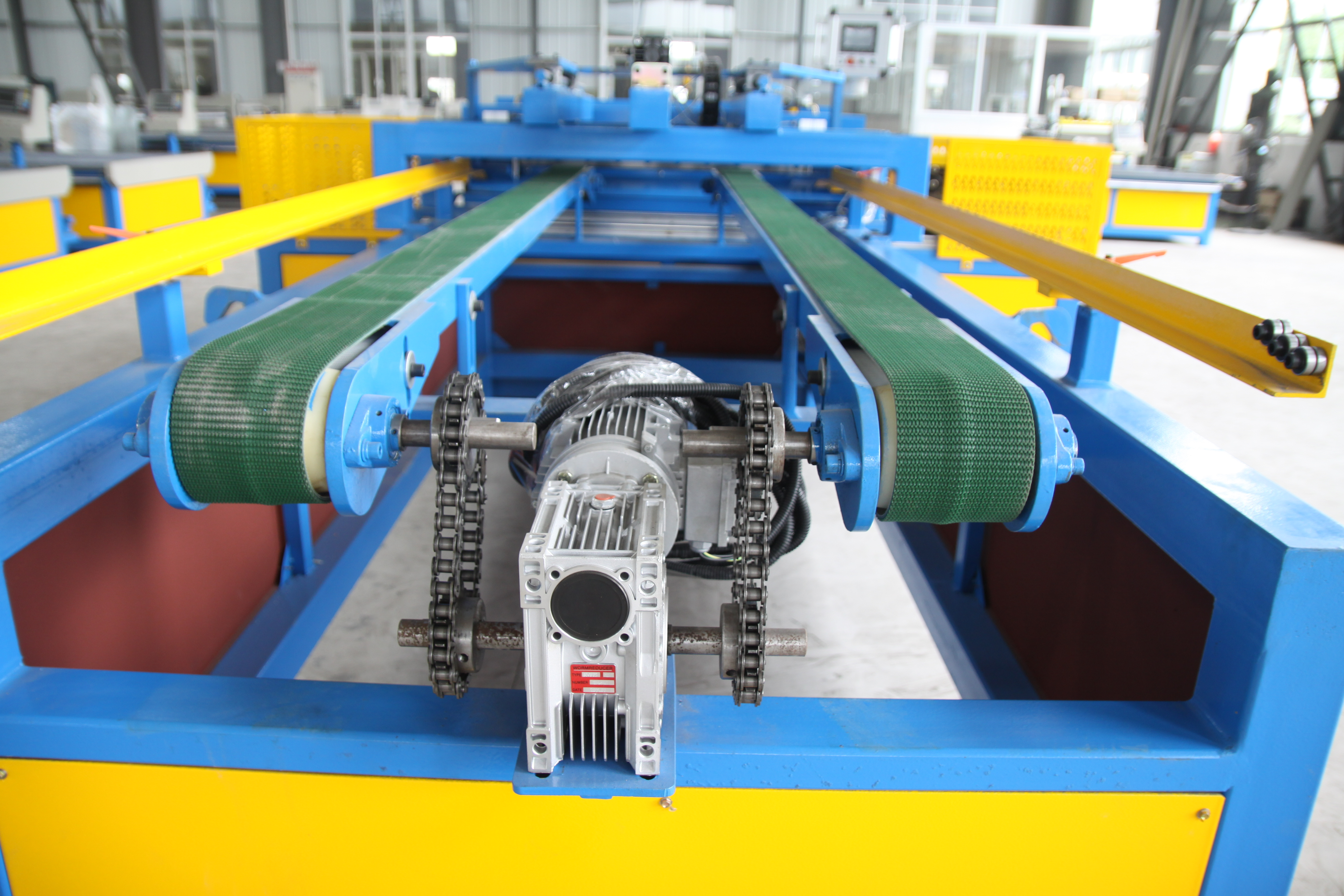

The main components of the machine

The shaft roller is the main part of the rolling machine. Its upper roller diameter is 130mm, the lower roller diameter is 120mm, and the working length is 1600mm.

The frame is divided into a left frame and a left frame, which are fixed on the base with bolts, and the reducer is driven by a motor to drive the lower roller.

$3,189.00$2,950.00 -

Compare

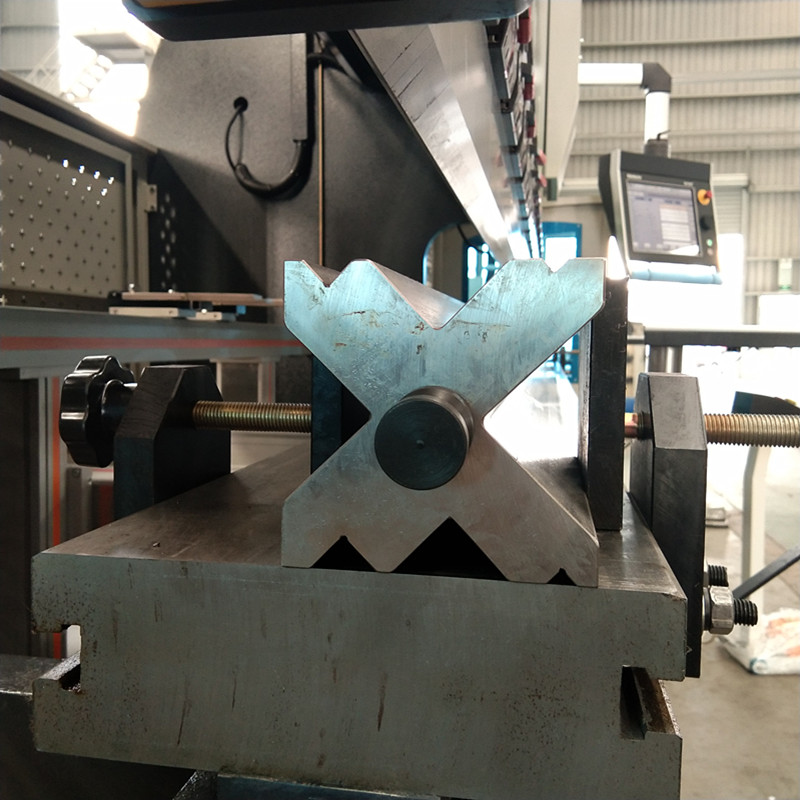

Delem DA66T Control System 6+1 Axis CNC Hydraulic Press Brake CNC Bending Machine with Laser Protection

0 out of 5(0)Main Features

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to

fully guarantee the intensity and rigidity of all the components.

2.The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption

reduction.

3.The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design

and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly

inspection)

4.Plate stock—-physical and chemical inspection—-Plate Pre-treatment (Rust-Cleaning) — CNC flame Cutting– Cutting the

welded joint—-Group Welding—-Gas Shielded Welding—Ageing treatment—-Milling Planer working—-The Assembly of finished

products

5.The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and

milling machine to ensure several geometric accuracy of the main machine.

6.The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded

situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the

working table and ram when work to guarantee good straightness and uniformity in angle$50,000.00$47,000.00 -

Compare

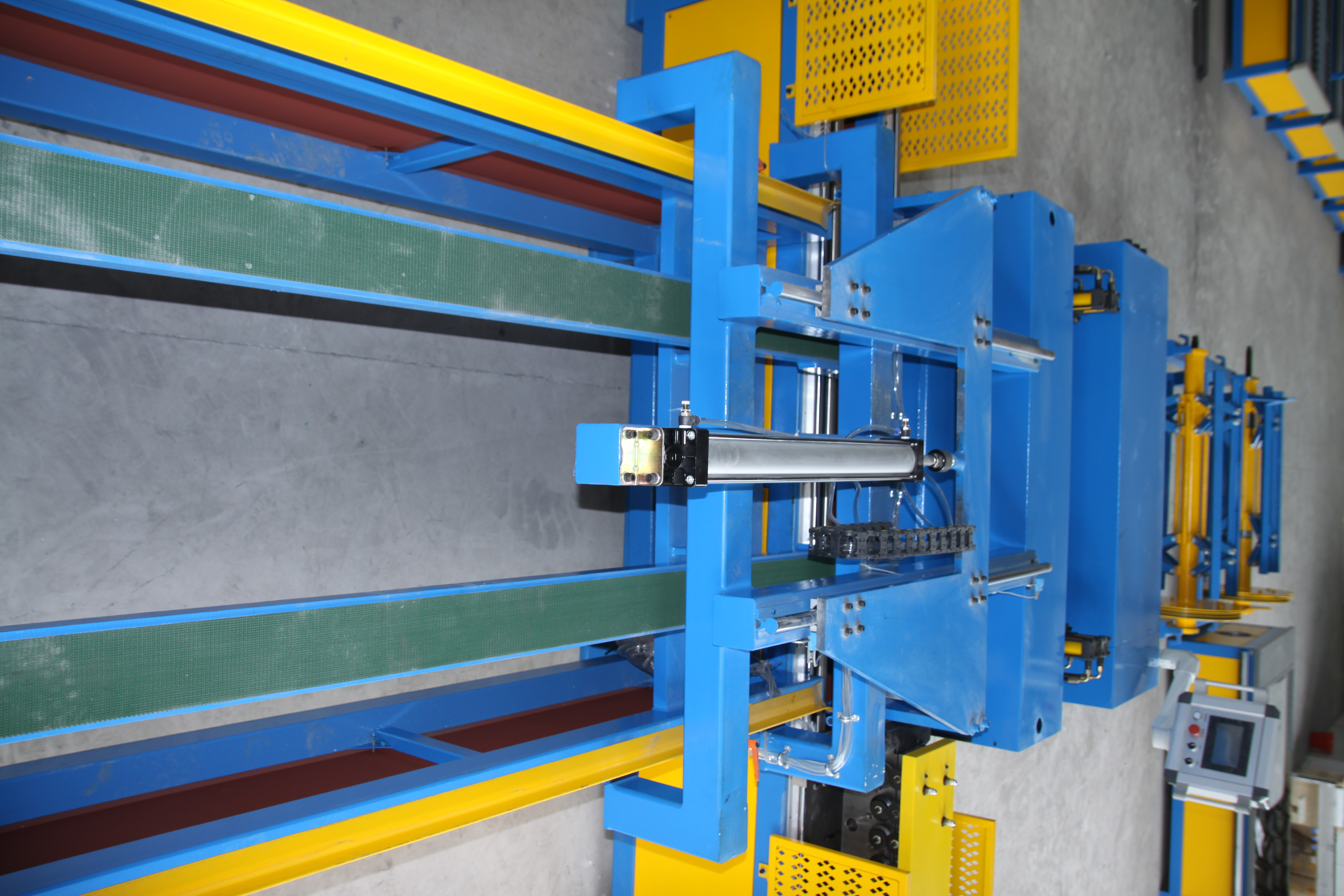

Super Auto Duct Line 4 Air Hose Blast Pipe Sheet Metal Square Processing Tools CNC HAVC Making Production Machine

0 out of 5(0)Super Auto Duct Line 4 Air Hose Blast Pipe Sheet Metal Square Processing Tools CNC HAVC Making Production Machine

Main Import Configuration:

1.Cylinder inported form Germany Festo

2.Beijing Huade plus hydraulic system fo Taiwan

3.Germany’s Siemens system

4.Taiwan Hiwin linear guideways

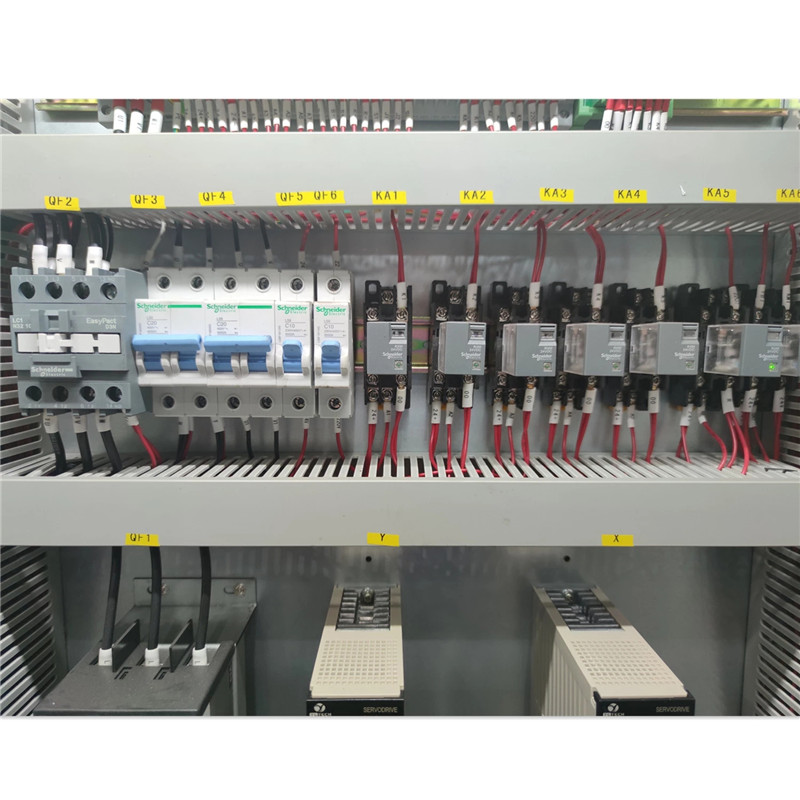

5.Schneider electrical system

Basic Configuration

1.Two electnic coil cradles ,4 material trays(5-7t each roll)

2.One rack

3.One host(line 2 host)

4.One mechanical arm clutching ,locating and transferring platform

5.One displacement type locking machine

6.One duplex TDF flange forming machin

7.One duplex angle steel flange forming machine

8.One set of computer controlling system

$38,900.00$34,750.00 -

Compare

Main Features

All the components of the machine are designed under the instruction of the Computer aided design and software of CAD/CAE/CAM to

fully guarantee the intensity and rigidity of all the components.

2.The whole body under total wielded, thickness and reliable in machine body with high-rigidity and good in shock absorption

reduction.

3.The machine structure are composed by body frame, working table, slide block, main cylinder and backgauge.The advantage design

and produce style can ensure the machine usage and high precision.The main produce procedure as below(all process under strictly

inspection)

4.Plate stock—-physical and chemical inspection—-Plate Pre-treatment (Rust-Cleaning) — CNC flame Cutting– Cutting the

welded joint—-Group Welding—-Gas Shielded Welding—Ageing treatment—-Milling Planer working—-The Assembly of finished

products

5.The machine body, Slide Block, Working table and other main components are under one time clamping of large landing boring and

milling machine to ensure several geometric accuracy of the main machine.

6.The machine is greatly enhanced in anti-torque and electronic load resistance. Machine can normally work in full loaded

situation. Working table, Upright Column, Crossbeam and Ram are good and high in design rigidity. Little deformation between the

working table and ram when work to guarantee good straightness and uniformity in angle$8,400.00$7,150.00 -

Compare

Automatic Mechanical Bending Rolling Round Machine Three Roller Bender Processing Plate And Metal Sheet

0 out of 5(0)Mechanical 3 Roller Plate Sheet Metal Rolling Bending Machine with Factory Price

The main components of the machine

The shaft roller is the main part of the rolling machine. Its upper roller diameter is 130mm, the lower roller diameter is 120mm, and the working length is 1600mm.The frame is divided into a left frame and a left frame, which are fixed on the base with bolts, and the reducer is driven by a motor to drive the lower roller.

$10,000.00$7,990.00 -

Compare

Simple Operation Sheet Bending Machine /Plate Symmeetrical 3-roller Rolling Machine / Electric Rolling Machine

0 out of 5(0)Main Features:

(1) Side of the workpiece before use in the pre-bending machine for bending to the effective point of view (when the original

board processing)

(2) To make the next roll rotation, bring materials on board with the rotating roll, the sheet metal rolled into the arc.

(3) The motor for positive and negative movement, and gradually roll on the pressure, repeatedly, thereby enabling the

workpiece gradually forming to requirements.

(4) Taking out the workpiece from the rolling roller.$1,450.00$950.00

Reviews

There are no reviews yet.